Have you ever come across a broken appliance that you couldn’t bear to get it thrown away? That’s what happened to me recently when I found a broken desk fan outside my neighbor’s apartment. They had placed it outside to be thrown out, but I saw the potential in it and knew I had to save it. The blades had snapped off, but I was determined to fix it and make it usable again. But rather than start searching for a replacement part and buy a new fan, I decided to take matters into my own hands and fix the broken blades using my 3D printer.

First, I had to design the replacement blades in a CAD software. I used Fusion 360 for this purpose. This was no easy task, as I had to make sure the blades were the exact same size and shape as the original ones. But with some trial and error, I was eventually able to create a design that fit perfectly in the metal enclosure of the fan.

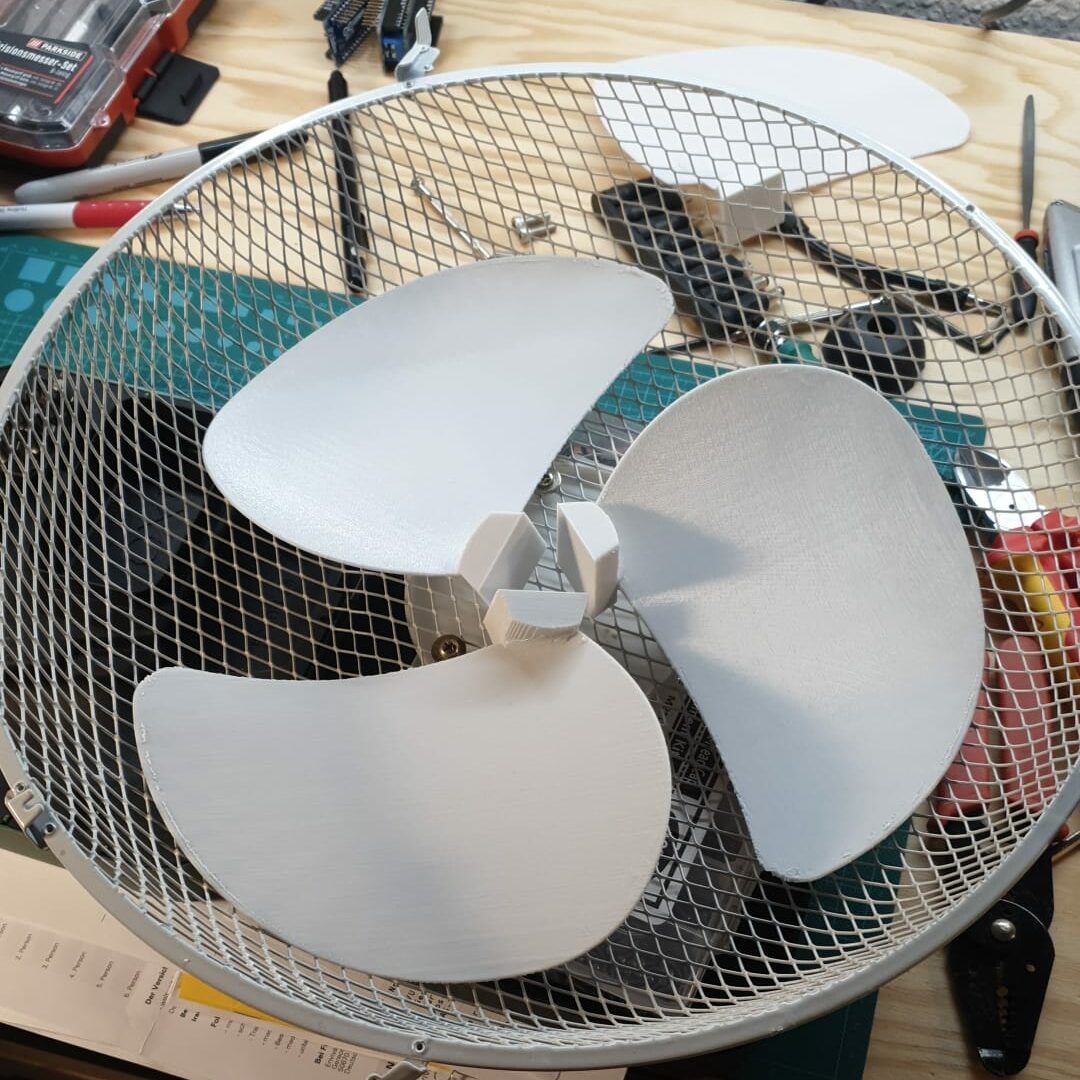

One of the biggest challenges I faced during the design process was the fact that the complete assembly of the fan blades with its hub was larger than the surface of my 3D printer. This meant that I had to split the design into multiple parts and print them separately.

First, I designed and printed the hub, which was relatively simple. Then, I modified the blade design so that they could be attached to the hub once they were printed. This required me to add a tapered base to the blades and corresponding negative shape on the hub.

Next, I printed out the 3 blades using my 3D printer with white PETG filament. This took a few hours, but the end result was worth it. The printed blades were strong and durable, and fit seamlessly onto the fan.

I must say that I was pleased with the results. Overall, this project was a fun and rewarding experience that taught me the joy of fixing things rather than throwing them away.

If you’re inspired by this project and want to discuss similar ideas, don’t hesitate to contact me.